Through our Advanced Engineering services, Avalign is able to support, collaborate, augment and innovate with and for our customers. We understand how important it is for our technical group to build relationships to foster mutual trust and understanding of our customers’ specific needs. Our engineers in product development, manufacturing and quality work collaboratively with customers in all phases of new product development and supply chain management. This high touch, prototype to production (P2P) approach has yielded a proven track record from simple to complex and small to large scope projects. Our customers have shortened their product development and manufacturing timelines while reducing total cost and minimizing design changes after design transfer for the end result of more successful product launches.

Support

Our manufacturing engineers and quality engineers are embedded in the operational teams within each of our divisions. Design for Manufacturing (DFM) reviews are a routine value added service we provide to all our customers. Design for Inspection (DFI) reviews are another value added service aimed at maximizing accuracy while minimizing the impact of inspection on both cost and lead time through efforts such as in process inspection, statistical process control (SPC), and methods recommendations (vision and imaging systems, comparators, gages, CMMs, etc.) that drive changes to dimensions, tolerances and GD&T implementation. Both DFM and DFI services are best leveraged prior to design freeze or drawing release for production when development engineers are most able to implement changes.

Collaborate

Our product development engineers are an Avalign team providing collaborative support across all divisions from their Fort Wayne location. Our project managers embedded in both the Avalign product development team and the division advanced engineering teams. Design for Cost (DFC) is a value added service aimed at balancing user needs, design inputs, features and benefits and total system cost. We accomplish this through engineering problem solving at the individual instrument level, through scope management recommendations at the system level, and through routine cost estimations throughout the new product development cycle. Project management extends the reach of our customers’ own project management by integrating our DFM, DFI and DFC activities in the planning cycle to avoid downstream bottlenecks that occur when vendor engagement first occurs during design transfer. Our project management all extends visibility to our customers’ project management through shared process management to avoid the “black box” paradigm between PO and delivery.

Augment

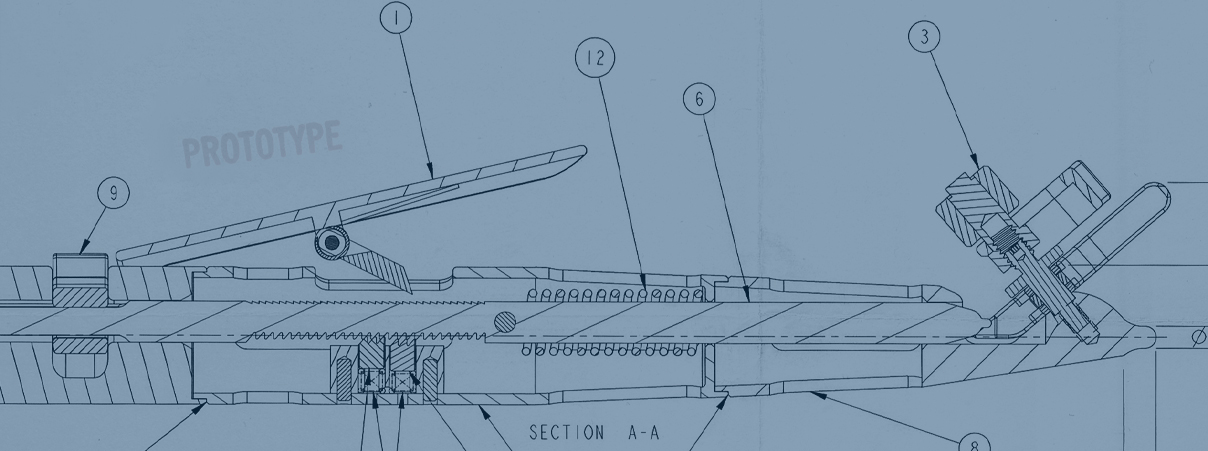

Sometimes there aren’t enough resources or there isn’t enough time or someone has successfully solved a similar problem before. For these occasions, the Avalign product development team is able to step in to augment our customers’ development teams by taking on full development responsibility for single instruments or entire systems. Our engineers can create implants and instruments with the core development deliverables of CAD models and drawings with tolerance analyses, or they can take on advanced development responsibilities through integrated design controls within our customers’ own design control systems. Our Augment services build on the same visibility that has made our collaboration successful by avoiding the “black box” paradigm between development order and product specification delivery.

Innovate

In addition to the customer driven activities where we Support, Collaborate and Augment our customers, the Avalign product development team designs products that are primarily Class I non-implant specific instruments that provide value to our customers through speed to market by leveraging our technologies and development expertise. We also provide Collaboration for successful implementation of our proprietary technologies: Flex Technology and Self-Retaining Technology. See the Avalign Innovations page for more information.